What is AEM Electrolysis?

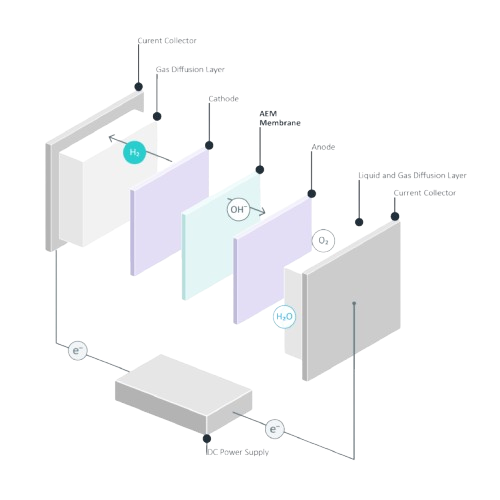

AEM (Anion Exchange Membrane) electrolysis is a water-splitting technology used to produce hydrogen. It works inside an AEM electrolyser, a device that separates water molecules into hydrogen (H₂) and oxygen (O₂) by moving negatively charged ions (anions) through a special membrane.

How It Differs from Other Electrolysis Methods

Unlike Proton Exchange Membrane (PEM) electrolysis, which requires expensive noble metal catalysts like platinum, AEM electrolysis can use lower-cost transition metal catalysts. It operates in a mildly alkaline environment, similar to alkaline electrolysis, but with fewer water purity requirements. This reduces handling risks and makes the system easier to maintain.

Hydrogen Production with AEM Electrolysers

An AEM electrolyser produces high-purity green hydrogen (99.9% or up to 99.999% with drying) at pressures up to 35 bar, using only water and renewable electricity. This makes it a cost-effective and scalable solution for clean hydrogen production.

What are the benefits of AEM Electrolysis?

AEM electrolysis has several benefits over other types of electrolysis. Unlike PEM electrolysis, it doesn’t need expensive materials like iridium or titanium, using more affordable metals instead. It's easy to scale, modular, and efficient, making it great for dynamic renewable energy setups. AEM electrolysers also handle intermittent operations well and are more sustainable since they don’t rely on scarce materials. Overall, they offer high performance with less maintenance compared to alkaline systems.

| Feature | AEM Electrolysis | PEM Electrolysis | Alkaline Electrolysis |

|---|---|---|---|

| No Intermittent Operation | Yes (Good performance with variable renewable energy) | Limited (Somewhat sensitive to load changes) | No (Struggles with dynamic operation) |

| Iridium-free | Yes (Uses transition metals, no rare iridium) | No (Requires iridium for the catalyst) | Yes (Uses nickel and other non-precious metals) |

| Top Efficiency | High Efficiency (Fast startup and high performance) | High Efficiency (But comes at a higher cost) | Moderate Efficiency (Lower efficiency with intermittent renewable energy) |

| Scalable | Yes (Easy to scale for different production levels) | Yes (Highly scalable but expensive for larger systems) | Yes (Scalable, but requires more maintenance for larger units) |

| Modular | Yes (Modular design for flexible integration) | Yes (Highly modular with custom solutions) | Yes (Supports modular setups for large-scale operations) |

| High Performance | Yes (Excellent performance, especially with renewable integration) | Yes (High performance but cost-intensive) | Moderate (Less efficient for dynamic operations) |

| Dynamic Response | Yes (Adapts well to renewable energy fluctuations) | Limited (Doesn’t handle variable load as well as AEM) | No (Struggles to keep up with fluctuating energy sources) |

| Intermittent Operation | Yes (Designed for intermittent renewable energy operation) | Limited (Less efficient during intermittent operation) | No (Doesn’t perform well with intermittent power) |

| Usage of Scarce Materials (Titanium, Iridium) | No (Uses low-cost materials, reducing reliance on rare resources) | Yes (Requires iridium and titanium for optimal performance) | No (Uses more common materials like nickel and iron) |

Key Advantages of AEM Electrolysis

AEM electrolysis provides high operational flexibility, matching hydrogen output to the fluctuating energy from renewable sources. Its fast response time allows quick adjustments to energy load changes, making it ideal for intermittent renewables. The technology’s compact and modular design ensures a small footprint and scalable production to meet specific needs. AEM also promotes price stability by avoiding expensive materials like iridium, which helps with supply chain reliability. Finally, AEM is future-proofed, as its components do not rely on non-degradable PFAS materials, ensuring compliance with upcoming regulations.

It produces hydrogen in a way that adjusts to the energy changes from renewable sources.

Quickly adjusting up or down to changes in energy from renewable sources that aren't always constant.

AEM technology doesn’t use costly materials like iridium, helping keep prices steady and making it easier to get the supplies needed.